GENERAL INFORMATION

Modular roller tracks for idle handling.

Modular roller tracks for idle handling.

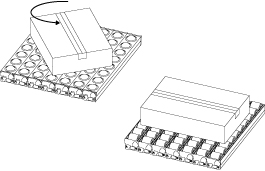

They can be used to create sliding and containing benches suitable for several applications in different fields: feeding and discharging benches in construction machinery, storage and picking systems, packaging machinery, etc.

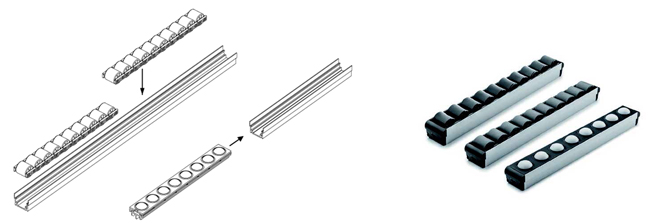

Modularity

The roller track can be easily assembled by fixing the roller or ball elements inside the appropriate aluminium anodised profiles. The particular section of the profile allows the snap-in assembly of the roller and ball elements into the profile without the need for screws or other fasteners.

Substitution

The roller and ball elements may be removed and replaced quickly and easily, without disassembling the entire roller track. The aluminium profile can be reused.

Sliding and quiet operation

The features of the materials of the rollers / balls and relative holders allow friction to be minimized and there is no need for lubrication maintenance.

High load capacity

The roller track ensures a high load capacity, thanks to a maximum capacity for single roller of 360N (PA rollers) and 150N (TPU rollers).

High impact strength

The roller elements are characterized by a high capacity to absorb shocks due to drop of material on the roller track.

Handling of delicate materials

The thermoplastic (TPU) polyurethane rollers, anti-scratch and antitrace material, are also suitable for handling delicate materials such as glass and wood.

Omnidirectional handling

The technopolymer acetal resin based (POM) balls allow to handle the material easily in any direction.

* Trademark application

-

Generals

-

1. Plastic materials

- 1.1 Mechanical strength

- 1.2 Thermal resistance

- 1.3 Strength and surface hardness

- 1.4 Resistance to chemical agents

- 1.5 Resistance to atmospheric agents and uv rays

- 1.6 Flame resistance

- 1.7 Electrical properties

- 1.8 Surface finish and cleanability

- 1.9 Compliance with international standards

- 1.10 Competence of Elesa+Ganter technical department

- 2. Metal materials

- 3. Other materials

- 4. Machining tolerances

- 5. Fixed handles

- 6. Assembly measures

- 7. Special executions

- 8. Colours

- 9. Test values

-

10. Technical tables

- 10.1 Conversion tables

- 10.2 DIN 79 Square holes and shafts

- 10.3 DIN 6885 Keyways

- 10.4 GN 110 and GN 110.1 Transversal holes

- 10.5 DIN 13 ISO Metric threads

- 10.6 DIN 228 Cylindrical GAS-BSP threads

- 10.7 DIN EN ISO 898-1 | DIN EN 20898-2 Strenght values

- 10.8 DIN ISO 286 ISO-Fundamental tolerances

- 10.9 IP Protection Classification

- 10.10.1 PFB | PRB Thread locking with jamming action Polyamide patch coating/ Polyamide complete coating

- 10.10.2 MVK Thread locking gluing Micro encapsulation precote 80 (red)

- 10.11 Stainless Steel characteristics

- 10.12 Surface treatments

- 10.13 Carbon steel, zinc alloys, aluminium, brass characteristics

- 10.14.1 Duroplast, elastomer, technopolymer and rubber characteristics

- 10.14.2 Duroplast, elastomer, technopolymer and rubber characteristics

- 10.14.3 Duroplast, elastomer, technopolymer and rubber characteristics

- 10.15 Load ratings U-Handles

- 10.16 Load ratings metal hinges

- 10.17 Strength of indexing plungers

- 10.18 Assembly sets GN 965 and GN 968

- 11. Vibration-damping elements

-

1. Plastic materials

- Hygienic design

- Operating Elements

- Clamping knobs

- Control elements

- Rotary controls

- Indexing elements

- Joints

- Transmission elements

- Levelling elements

- Hinges

- Latches

- Toggle, power and hook clamps

- Accessories for hydraulic systems

- Tube clamp connectors

- Castors and wheels

- Magnets

- Conveyor components

- Linear slides

- Vibration mounts

- Vacuum components

- Elastomer springs