Description

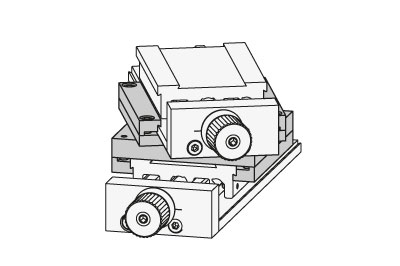

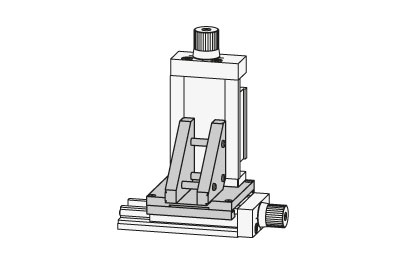

The adjustable slide units GN 900 (see page 664) are a work holding system which can accommodate almost any type of application.

Four standard sizes are available with different slide widths i.e. 30, 50, 80 and 120 mm which again cover almost a full specific range of applications

As standard for each slide width there are externally guided slides with different openings. The design of these adjustable slide units can accommodate outsize components.

These adjustable slide units can be combined with a range of adaptor components to bring the adjustable slide unit into any required position whether horizontal, vertical or any other angular position for machining operations. A unique clamping technique allows simple and rapid workpiece clamping.

All components are in aluminium, stainless steel and plastic material which makes the adjustable slide units with control knob (Type D) a corrosion free unit.

A range of different operating features with or without digital position indicators is also available. In addition there is a range of other accessories.

Other features

- slides in anodized aluminium

- high load ratings

- favourable friction values

- high quality slideways by virtue of the anodized surface hardness

- backlash free shaft adjustment

- fine adjustment to 0.05 mm

- scale rings with zero position

- adjustable clamping levers to suit the positioning of the slides

Application examples

- Precision positioning of soldering / welding heads

- Adjustment of inkjet printers

- Adjustment of measurement cameras

- Adjustment of laser heads

- Re-adjustment of back stops

- Adjustment of sensors

The manually operated rotary table GN 900.6 (see page 677) is a positioner which extends the range of applications for the adjustable slide units considerably. This rotary table can, of course, also be used without the adjustable slide units.

The adjustable assembly X-Y consisting of two adjustable slide units GN 900 (see page 668) and an X-Y connecting set GN 900.2 (see page 673) with a mounting plate GN 900.4 (see page 675).

The adjustable assembly X-Y-Z consisting of three adjustable slide units GN 900 (see page 668), X- and Z-axis with position indicator, plus rotary table GN 900.6 (see page 677) mounted on Z-axis, assembled on mounting plate GN 900.4 (see page 675).

The adjustable assembly X-Y consisting of two adjustable slide units GN 900 (see page 668), Y-axis with rotary plate GN 900.5 (see page 676) positioned at a horizontal cross angle of 120°.

Special execution

Adjustable slide unit type S with a mounted pneumatic cylinder.

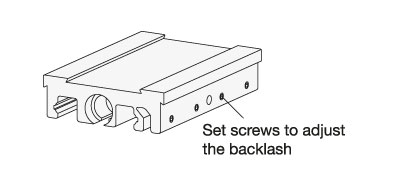

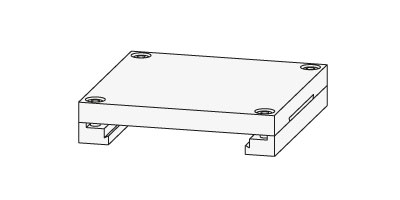

The outer slide is made of a press formed block of anodized aluminium extrusion which is usually the moving part. As a standard there is usually one outer slide size for each outside slide length on which the connecting sets GN 900.2 (see page 673)and mounting plates GN 900.4 (see page 675) and rotary plates GN 900.5 (see page 676) can be mounted. Special lengths can be supplied.

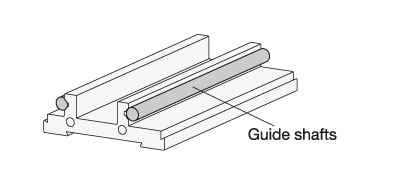

The inner slide is also made of a press formed block of anodized aluminium extrusion which is the carrier. The guides are made of two high grade shafts in stainless steel.

High load ratings and favourable friction values is achieved by the anodized hard guide surfaces.

The length of the inner slide is determined by the length of the outer slide by adding the stroke.

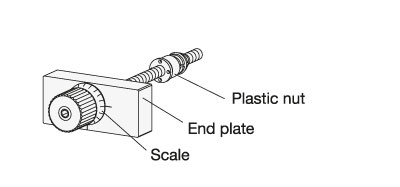

The backlash free drive unit consists of an end plate and a preloaded stainless steel spindle, ball bearing mounted, and a preloaded plastic nut (temperature resistant from -20 °C up to + 80 °C).

The thread pitches are: Slide size b = 30 : 0.5 mm Slide size b = 50, 80, 120 : 1.0 mm

For positioning a scale is used (one graduation line = 0.05 mm adjustable range) which can be reset to „0“.

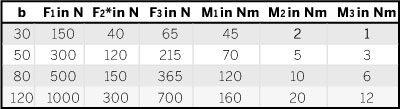

Permissible load values of the adjustable slide units GN 900

* F2 is the max/permissible sliding thrust

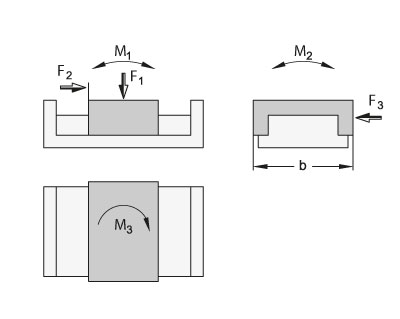

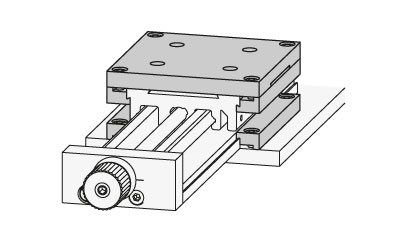

Fastening units GN 900.1 (see page 672) consist to two mounting rails. On the latter, the adjustable slide unit is mounted on a base plate from the operator’s side.

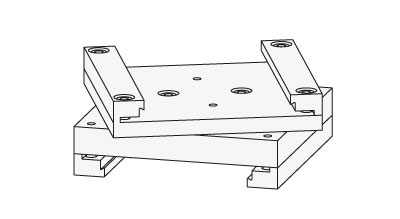

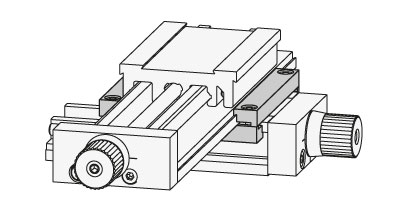

Connecting sets GN 900.2 (see page 673) consist of four rails. With the latter, two adjustable slide units are combined to form an adjustable assembly X-Y (or Y-Z).

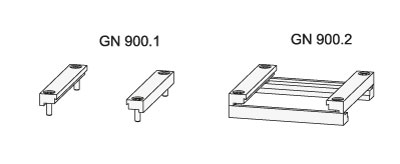

Connecting sets GN 900.3 (see page 674) consist of two plates. With the latter two adjustable slide units combined to form an adjustable assembly X-Z (or Y-Z). If this slide has to be parallel to the reference axis this is achieved by using an additional plate (Type P).

Mounting plates GN 900.4 (see page 675) serve as an adaptor plate to be machined on the side which is required for mounting. By using a machined mounting plate further work on the actual slide can be eliminated.

The plate is fixed with the fastening unit GN 900.1 (see page 672) on the adjustable slide unit.

The rotary plate GN 900.5 (see page 676) allows oblique positioning of the adjustable slide unit at any angle

Adjustable slide unit with mounting plate GN 900.4 (see page 675) fitted to the base plate by using fastening unit GN 900.1 (see page 672).

Adjustable slide unit X-Y, adjustable slide unit is fitted to the base plate using connecting set GN 900.2 (see page 673).

Adjustable slide unit X-Z, adjustable slide unit is connected together using the connecting set GN 900.3 (see page 674).

Adjustable slide unit X-Y, Y-slide with rotary plate GN 900.5 (see page 676) set shown in an angular position.