MVK Thread locking gluing Micro encapsulation precote 80 (red)

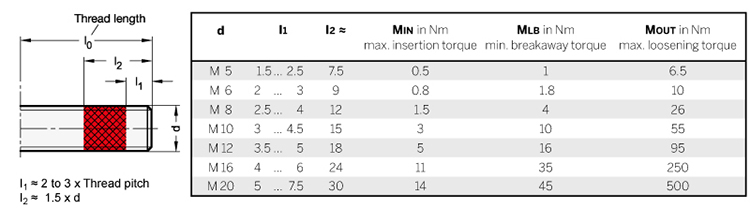

The torque value comply with DIN 267 Part 27. They are based on a test of a thread without preload with a nut thread of 6H at room temperature. For thread lengths l0 < l2, l2 is reduced in such a way that one to two thread turns are not coated at the end of the thread.

Description

The principle of micro encapsulation MVK (gluing) consists of a liquid plastic material and hardener encapsulated in a thin polymer film which is embedded in a lacquer like carrier deposited in patch form an a thread. This patch dries and the component can be stored and handled in a normal manner.

When fitting a bolt with this patch the two capsules will burst under the pressure and friction between the two threads. The liquid plastic material and hardener will mix leading to a chemical reaction which will harden the glue, thus giving the required thread locking.

The setting of the mixture will start after 10 – 15 minutes. Sufficient hardness is achieved after about 30 minutes but complete setting is reached after 24 hours.

Adjustment and setting process must be completed within about 5 minutes.

The thread locking can be cracked by applying the MOUT torque on the thread or alternatively by heating the component over +170 °C. It is not recommended to re-use the thread.

Threads, free from oil and grease give increased strength of locking action.

Components treated with this process can be stored for up to 4 years.

Features

– Thread locking to the highest order to prevent the self loosening and component loss even under vibration. Not suitable for adjustable bolts or screws.

– This security aspect may be essential for certain applications of standard parts. Stockholding of liquid glue is eliminated.

– Low insertion torque

– Temperature resistant from – 40 °C up to 170 °C

– Excellent chemical stability

GPC Tightening with thread coating Precote 5 (white)

Description

Precote 5 is a non-reactive, film-forming emulsion with mineral solids for coating threaded parts.

The coating generates a seal against gases and liquids in threaded parts, both in cylindrical / cylindrical and in cylindrical / conical pairs. Corrosion in the threaded connection is prevented.

The coating is solvent-free, dry and non-sticky. It is non-hazardous for health.

The minimum storage stability in unmounted state is 4 years.

Features

– The sealing coat is a captive element of the locking screw. It saves storing and mounting locking materials.

– The sealing effect sets in after mounting, no curing time is required.

– The friction rating of the thread remains virtually constant, the working-loose torque is low, max. reusable once.

– Sealing effect of thread: cylindrical / cylindrical < 15 bar cylindrical / conical > 50 bar

– Temperature resistance: from – 50 ºC to 180 ºC

– Good chemical resistance, e.g. against oils, water, petrol and solvents

-

Generals

-

1. Plastic materials

- 1.1 Mechanical strength

- 1.2 Thermal resistance

- 1.3 Strength and surface hardness

- 1.4 Resistance to chemical agents

- 1.5 Resistance to atmospheric agents and uv rays

- 1.6 Flame resistance

- 1.7 Electrical properties

- 1.8 Surface finish and cleanability

- 1.9 Compliance with international standards

- 1.10 Competence of Elesa+Ganter technical department

- 2. Metal materials

- 3. Other materials

- 4. Machining tolerances

- 5. Fixed handles

- 6. Assembly measures

- 7. Special executions

- 8. Colours

- 9. Test values

-

10. Technical tables

- 10.1 Conversion tables

- 10.2 DIN 79 Square holes and shafts

- 10.3 DIN 6885 Keyways

- 10.4 GN 110 and GN 110.1 Transversal holes

- 10.5 DIN 13 ISO Metric threads

- 10.6 DIN 228 Cylindrical GAS-BSP threads

- 10.7 DIN EN ISO 898-1 | DIN EN 20898-2 Strenght values

- 10.8 DIN ISO 286 ISO-Fundamental tolerances

- 10.9 IP Protection Classification

- 10.10.1 PFB | PRB Thread locking with jamming action Polyamide patch coating/ Polyamide complete coating

- 10.10.2 MVK Thread locking gluing Micro encapsulation precote 80 (red)

- 10.11 Stainless Steel characteristics

- 10.12 Surface treatments

- 10.13 Carbon steel, zinc alloys, aluminium, brass characteristics

- 10.14.1 Duroplast, elastomer, technopolymer and rubber characteristics

- 10.14.2 Duroplast, elastomer, technopolymer and rubber characteristics

- 10.14.3 Duroplast, elastomer, technopolymer and rubber characteristics

- 10.15 Load ratings U-Handles

- 10.16 Load ratings metal hinges

- 10.17 Strength of indexing plungers

- 10.18 Assembly sets GN 965 and GN 968

- 11. Vibration-damping elements

-

1. Plastic materials

- Hygienic design

- Operating Elements

- Clamping knobs

- Control elements

- Rotary controls

- Indexing elements

- Joints

- Transmission elements

- Levelling elements

- Hinges

- Latches

- Toggle, power and hook clamps

- Accessories for hydraulic systems

- Tube clamp connectors

- Castors and wheels

- Magnets

- Conveyor components

- Linear slides

- Vibration mounts

- Vacuum components

- Elastomer springs