Linear actuators

| Linear actuator | Fx in N | Fy in N for length l = | Fz in N for length l = | Mx in Nm | My in Nm | Mz in Nm | ||||

|---|---|---|---|---|---|---|---|---|---|---|

| 500 | 1000 | 1500 | 500 | 1000 | 1500 | |||||

| 18 | 400 | 80 | - | - | 65 | - | - | 1.5 | 4.5 | 4.5 |

| 30 | 850 | 500 | 70 | 15 | 550 | 55 | 10 | 6.5 | 15 | 15 |

| 40 | 1100 | 2150 | 250 | 65 | 1900 | 150 | 50 | 15 | 42 | 42 |

| 50 | 1750 | 3100 | 650 | 150 | 3100 | 650 | 150 | 29 | 69 | 69 |

| 60 | 2600 | 4550 | 1500 | 400 | 4550 | 1400 | 350 | 45 | 125 | 125 |

The load data are applicable to linear actuators GN 291, GN 292, GN 293 made of Steel (SCR) or Stainless Steel (NI).

The specified forces Fy and Fz cause a flexure of the guide tube of approx. 0.5 mm.

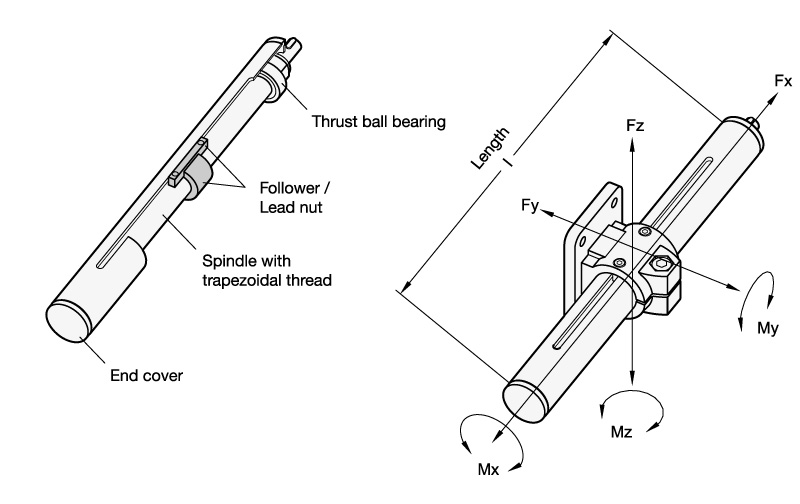

A lead nut moves in axial direction over the ball bearing trapezoidal thread spindle of the linear actuator. The follower ensures the anti-rotation and makes the link to the different linear actuator connectors. The linear actuators have been designed for manual operation (handwheel).

The positioning accuracy is 0.2 mm / 300 mm stroke, the maximum reverse play is 0.1 mm.

Guide tubes are available in chromed Steel (SCR) or Stainless Steel (NI) non-rusting. They are made with the tolerance range of precision steel tubes DIN 2391 or DIN 2462.

A wide variety of different components are available in the tube clamp connector program to fix the linear actuators in place and to upgrade these into linear actuator connectors.

Also, digital position indicators (DD52R / DD51) may be attached to measure the displacement or the positioning.

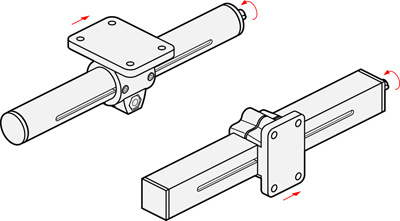

In applications where high torsion forces Mx occur, linear actuators with square tubing or double tube linear actuators should be given preference.

A wide variety of different components from the tube clamp connector program is also available for the square tubings. The linear actuator connectors are composed of two-part elements, with the effect that the precision of the square tubes involves no special requirements.

DESCRIPTION

Linear actuator GN 291 with right or left hand thread, with shaft journal at either one or both ends, with a linear actuator connector GN 146.1.

Square linear actuator GN 291.1 with right or left hand thread, shaft journal at either one or both ends, with a linear actuator connector GN 147.1.

DESCRIPTION

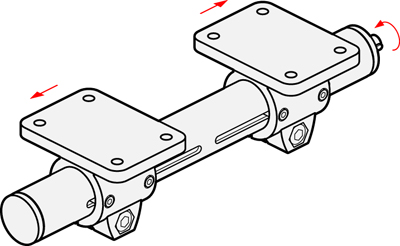

Linear actuator GN 292 with left and right hand thread, shaft journal at either one or both ends, with two linear actuator connectors GN 146.1, the two connectors move symmetrically.

Square linear actuators GN 292.1 on request.

DESCRIPTION

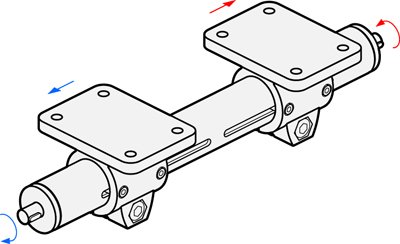

Linear actuator GN 293 with two separate threaded spindles, each with right or left hand thread with two linear actuator connectors GN 146.1, the two connectors move independently of one another.

Square linear actuators GN 293.1 on request.

-

Generals

-

1. Plastic materials

- 1.1 Mechanical strength

- 1.2 Thermal resistance

- 1.3 Strength and surface hardness

- 1.4 Resistance to chemical agents

- 1.5 Resistance to atmospheric agents and uv rays

- 1.6 Flame resistance

- 1.7 Electrical properties

- 1.8 Surface finish and cleanability

- 1.9 Compliance with international standards

- 1.10 Competence of Elesa+Ganter technical department

- 2. Metal materials

- 3. Other materials

- 4. Machining tolerances

- 5. Fixed handles

- 6. Assembly measures

- 7. Special executions

- 8. Colours

- 9. Test values

-

10. Technical tables

- 10.1 Conversion tables

- 10.2 DIN 79 Square holes and shafts

- 10.3 DIN 6885 Keyways

- 10.4 GN 110 and GN 110.1 Transversal holes

- 10.5 DIN 13 ISO Metric threads

- 10.6 DIN 228 Cylindrical GAS-BSP threads

- 10.7 DIN EN ISO 898-1 | DIN EN 20898-2 Strenght values

- 10.8 DIN ISO 286 ISO-Fundamental tolerances

- 10.9 IP Protection Classification

- 10.10.1 PFB | PRB Thread locking with jamming action Polyamide patch coating/ Polyamide complete coating

- 10.10.2 MVK Thread locking gluing Micro encapsulation precote 80 (red)

- 10.11 Stainless Steel characteristics

- 10.12 Surface treatments

- 10.13 Carbon steel, zinc alloys, aluminium, brass characteristics

- 10.14.1 Duroplast, elastomer, technopolymer and rubber characteristics

- 10.14.2 Duroplast, elastomer, technopolymer and rubber characteristics

- 10.14.3 Duroplast, elastomer, technopolymer and rubber characteristics

- 10.15 Load ratings U-Handles

- 10.16 Load ratings metal hinges

- 10.17 Strength of indexing plungers

- 10.18 Assembly sets GN 965 and GN 968

- 11. Vibration-damping elements

-

1. Plastic materials

- Hygienic design

- Operating Elements

- Clamping knobs

- Control elements

- Rotary controls

- Indexing elements

- Joints

- Transmission elements

- Levelling elements

- Hinges

- Latches

- Toggle, power and hook clamps

- Accessories for hydraulic systems

- Tube clamp connectors

- Castors and wheels

- Magnets

- Conveyor components

- Linear slides

- Vibration mounts

- Vacuum components

- Elastomer springs